Vavedt is offering complete control and information systems for efficient and safe furnace operation based on state-of-the-art PLC and PC technology.

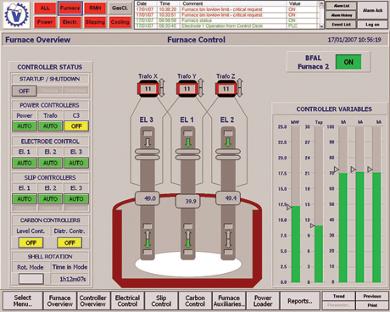

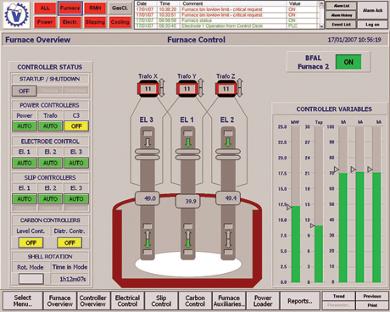

Electrical control

Slip control and monitoring

Automatic data logging

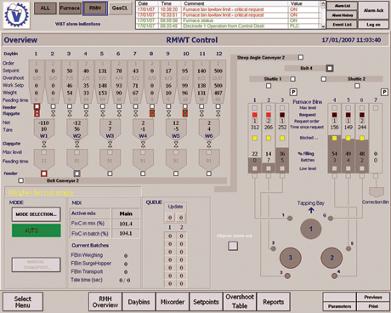

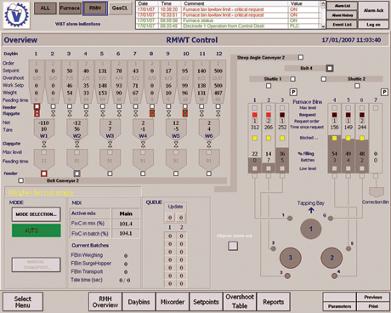

Raw material handling

Automatic batch queuing

Differential overshoot compensation

Automatic moisture correction for raw materials

Multiple setpoint selection

Furnace hopper zone correction

Carbon controller integration

Automatic restart in case of equipment failure

Report system including shift, day and week consumption

Historical report system

The control system for bag filter and powder treatment contains the following functions:

Automatic filter start up and shut down sequence

Automatic handling of extreme temperature and pressure values

Main fan automatic gas flow and power control

Automatic cleaning sequence for filter bags

Automatic cleaning pressure control system

Fully automated dust transport from filter hoppers to silos

Powder densification systems

Multiple, integrated operator stations

Integrated alarm system for all processes

Flexible, graphical trend system and historical logging.

Material control from reciept to shipment

Consumption and production handling

Analysis handling of raw materials and products

Yield calculations for process

Cost and budget measures for process

Integration with other management systems

Material recipes, production and sales

Operational data system

Down time analysis

Statistical process control

Advanced query and report system

Vatvedt Group

Olav Haraldssons gate 8-10

P. O. Box 74, N-1701 Sarpsborg, Norway

Telephone: +47 69 13 30 30

Telefax: +47 69 13 30 31