Improve productivity

Make use of best available technology

Energy costs

Raw material costs

Labour costs

Finished product quality requirements

Demands on working environment

Demands on external environment

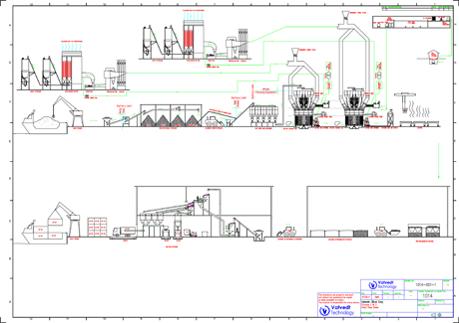

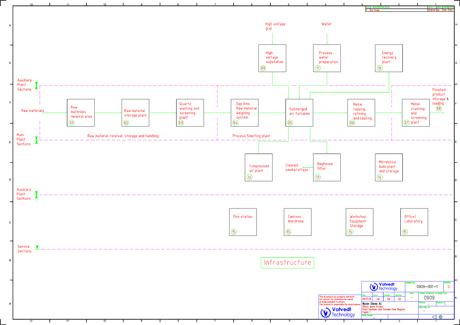

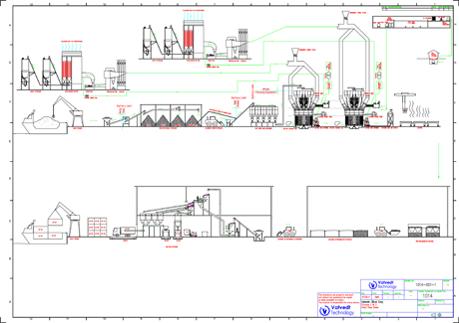

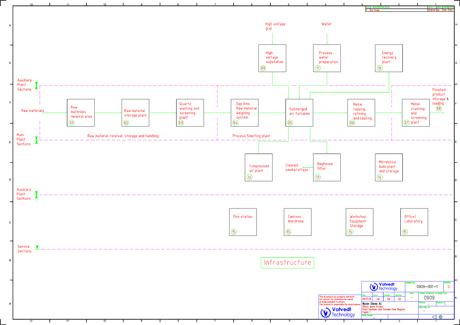

Greenfield projects for production of ferro alloys and related products

Installation of new furnaces in an existing plant

Overhaul, upgrading and capacity increase of existing furnaces

Capacity expansion studies

Evaluation of furnace operation and performance improvement

Process automation and process control

Ferromanganese and silicomanganese

Ferrosilicon and ferrosilicon based alloys

Silicon metal

Ferrochrome

Ferronickel

Calcium carbide

Closed, semiclosed and open furnaces

Stationary and rotating furnaces

Vatvedt Group

Bredmyra 8

P. O. Box 74, N-1701 Sarpsborg, Norway

Telephone: +47 69 13 30 30

Telefax: +47 69 13 30 31